The Benefits of Using a Digital Twin in Automation

There is a common misconception that digital twins are a concept for the future and not quite ready for prime time. That simply isn’t the case. Digital twins are already being used to significant effect across various industries.

In manufacturing, they’re being used to improve production and processes. Engineers of all types are using them to enhance complex mechanical projects in aviation, the automotive industry, and beyond.

According to some analysts, the digital twin market will grow from 6.9 billion USD in 2022 to 73.5 billion USD by 2027.

Automation will not be immune to the accelerated and widespread use of digital twins because the challenges they solve, and the benefits of digital twins are far too great to ignore.

What is a Digital Twin in Automation

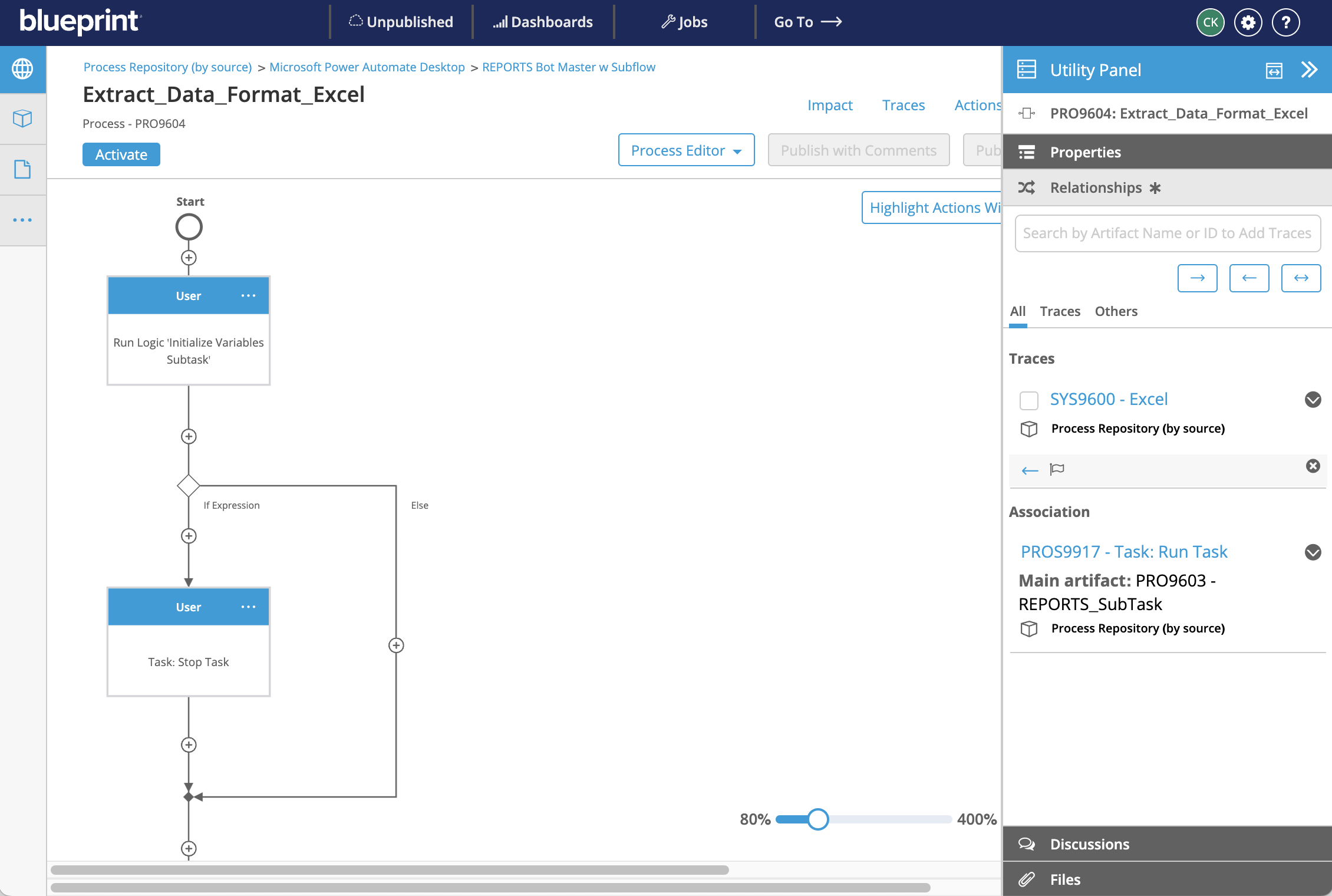

In automation, a digital twin is a digital copy of an automated process in a separate repository external to the RPA platform, where the actual automation is developed, deployed, and orchestrated.

The digital twin of an automation evolves as the automation itself evolves. If any changes are applied to the automation in the RPA platform, those changes are reflected in the twin, ideally in real-time or at least near real-time. Operational metrics (e.g., runs, last time run, number of issues, utilizations, and success rates) are also accessible and displayed where the twin resides so it can be monitored and continuously improved, just like any other digital twin in any other industry or application.

The Challenges Digital Twins Solve in Automation

Automation has delivered significant benefits for organizations that have adopted it, but the journey hasn’t been easy. There continue to be barriers and pain points that plague automation programs, creating bottlenecks, stifling scale, and throttling better returns.

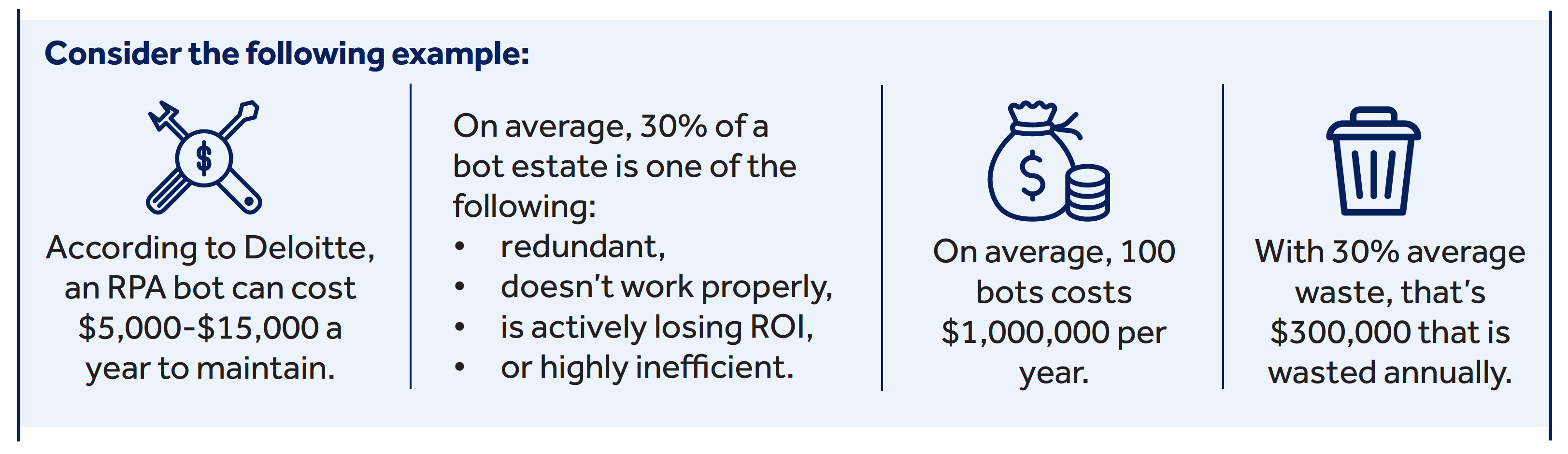

Those challenges include heavy maintenance burdens that eat away at ROI and a lack of visibility on automation estates hiding redundancies and inflating costs, just to name a few. One of the reasons the concept of digital twinning resonates so well in the automation space is its ability to help overcome those challenges.

This is how the implementation of digital twins in automation can help eliminate some of automation’s most significant pain points:

Inaccurate Documentation & No Audit Trails

Automations evolve. Unfortunately, the process design documents (PDD) they were designed on do not. The PDDs where automations are designed and delivered to developers remain static and are often lost. Companies are left without an audit trail or version history for their automated processes, leaving them unable to visualize and understand how their automations have changed over time.

Worse yet, the lack of accurate, up-to-date documentation in one central repository leaves organizations without the ability to fully understand what they actually have in their automation estates.

Heavy Maintenance Effort

When errors are thrown or outages occur for automations, normally, a highly-skilled technical resource needs to investigate the automated process, understand what it does, and identify where the error exists and the required corrective action.

A digital twin radically accelerates this process because it serves as a canvas for the automation that can quickly be reviewed to identify where the error is and mitigate downtime and lost business value.

Reactive Change Management

Currently, change management is highly reactive for the same factors that inflate maintenance efforts. Corrective action is only taken when automations fail.

Digital twins enable proactive management. When automation teams are alerted of an impending change – like a version update to an application that changes the dependent UI or a regulatory change – this can be reconciled in the repository where the digital twin resides, and the corrective actions can be coordinated with speed and ease.

Limited Performance Visibility

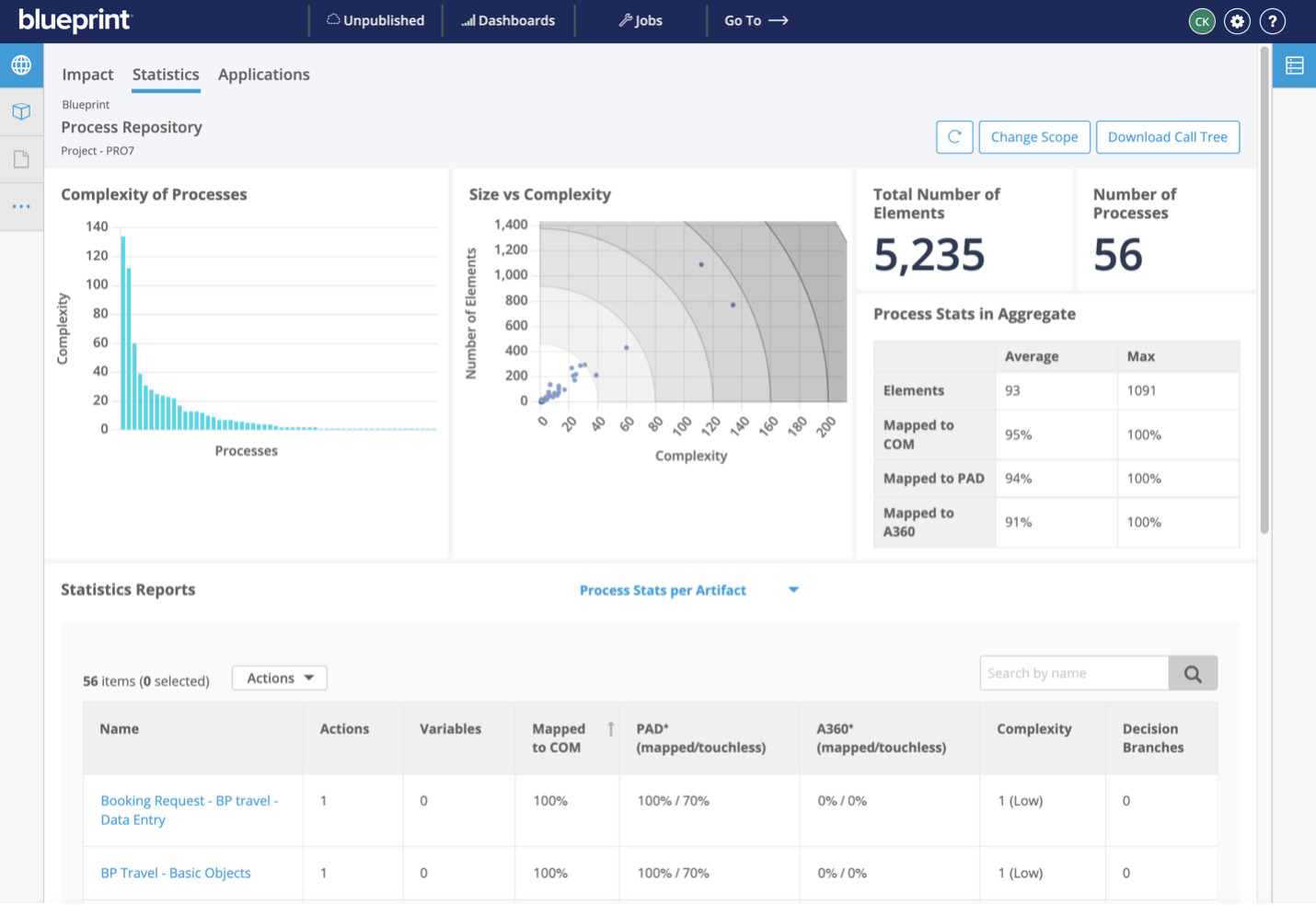

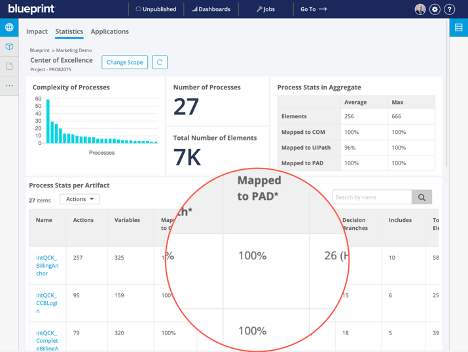

Most RPA execution platforms have a control room where operational data for automations can be tracked and monitored. Yet, they generally fall short in other areas of automation analytics that are just as important and impactful.

The use of digital twins in a separate repository opens the door to a wealth of invaluable insight like the complexity of that process, the applications, and systems it interacts with, where there might be redundancies in your estate, and which automations can be retired to reduce costs and increase returns.

Complexities in Understanding and Managing Estates Across Multiple RPA Tools

One of the biggest challenges the implementation of digital twins in automation addresses is the difficulty of managing automation practices across RPA tools. According to recent Blueprint research, 40% of all those surveyed reported using multiple RPA tools in their automation initiatives. Of those on a multi-vendor strategy, 74% claimed they had no plans to consolidate their automations under one roof.

While there are several reasons organizations use a multi-platform strategy, it does pose severe challenges by way of standardization, governance, and visibility. With automations spread across multiple tools, there is no single source of truth. Maintaining a digital twin for all automations in one central location, regardless of which RPA platform they’re designed, deployed, and orchestrated in, enables organizations to monitor, govern, and keep a pulse on their entire automation estate.

Digital twins solve many challenges currently confronting automation practices, but they continue to deliver benefits beyond just addressing those headaches.

The Benefits of Using a Digital Twin in Automation

What are the benefits of digital twins? In addition to all the above outcomes, organizations can realize by implementing digital twins in automation such as:

- Accurate documentation and detailed audit trails

- Reduced maintenance effort

- Proactive change management

- Better performance analytics and visibility, and

- Consolidated visualizations and understanding of automation estates spread out across multiple RPA platforms

There are several other ROI-increasing benefits you get from using digital twins in automation:

Enable Continuous Improvement

With a single source of unabated truth, organizations can continuously track and monitor their automations, including which ones are delivering value and which aren’t. On average, 30% of automation estates are redundant.

Digital twins enable you to see which automations can be optimized to further increase performance and returns, and which redundant automations can be retired to reduce operating costs from maintenance efforts or licensing costs.

Better Governance

Digital twins of all your automations in one place enable the application and enforcement of strong standards, collaboration, and general governance practices, whether it stems from coordinating maintenance, change management, or reporting.

Simplified RPA Migration and Re-platforming

It’s no secret that there is a lot of movement in the automation space as organizations ditch their legacy RPA platforms for next-generation intelligent automation solutions like Microsoft Power Automate.

Digital twins of your automations enable accelerated and simplified RPA platform migrations because you can perform feasibility assessments to evaluate the effort needed to switch to your destination platform of choice. Because there is also a digital version of your up-to-date automation, exporting the automation with a mapping engine that requires minor fit and finish touches dramatically reduces the effort needed and removes the manual re-coding once required.

Share this

Recent Stories

What is a Digital Twin? Everything You Need to Know

5 Ways Microsoft Power Automate Reduces Costs