What is a Digital Twin? Everything You Need to Know

Many credit the birth of the digital twin to Dr. Michael Grieves, who applied the idea to the manufacturing sector in 2002; however, the argument is often made that its origins can be traced even further back.

For example, during the Space Race (1955-1975), NASA would create a replica of each spacecraft they would send into orbit. These replicas were studied and used for simulation to gain insight into their performance and improve their space exploration initiatives.

It is here where this concept of a digital twin – an idea gaining a lot of momentum in the automation space – was born.

This article provides a detailed overview of what a digital twin is, the different kinds in use today, its benefits, and what a digital twin looks like in automation.

What is a Digital Twin?

A digital twin is a digital representation or copy of a process, service, or physical object. It’s essentially a digital or virtual model that mirrors an artifact and is updated with real-time data.

It’s used to provide an accurate reflection of an artifact, maintain a direct record of that artifact, study its performance, and improve it with the insight a digital representation with real-time data provides.

How Does a Digital Twin Work?

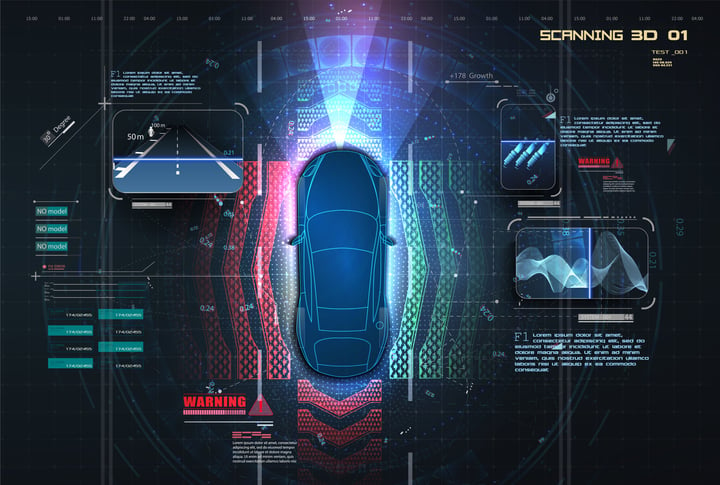

An example of a digital twin in the real world would be a digital representation of a car. The physical car would then contain sensors that feed performance data and metrics into a repository in real time.

In automation, a digital twin would be a copy of the automated processes that provides operational data such as:

- Runs

- Last time run

- Number of issues

- Utilizations, and

- Success rate

In many cases, digital twins can also be used to run simulations in a virtual environment to understand how changes to a process, service, or physical object can impact performance.

For a car, this may involve changing the contours of a car’s body to see how it impacts aerodynamics. For an automation, it may involve changing or removing a step in the process to see how it affects runtime.

The Different Kinds of Digital Twins

There are four fundamental types of digital twins that follow a progressive structure in terms of what they contain and represent:

- Parts or Component Twins – In this case, a part or component twin is the smallest example of a digital twin. It’s a digital representation of only one part of a larger process, service, or physical object. In our previous example of a car as a digital twin, an example of a component or part twin would be a digital representation of one piston in the car’s engine.

If we want to use a process as an example, a part or component twin would be opening an email with an invoice attached–a simple component or step in the larger activity of processing an invoice. - Asset Twin – An asset twin is just one rung up from a part or component twin. It’s a digital representation of how various components work together to form an asset. A good example would be a car engine. There are various components to an engine that work in conjunction to form a functional engine.

In our process example, an asset twin would be the process of opening an email, opening the attachment, and extracting the information from that invoice. - System or Unit Twins – A system or unit twin continues to get a bit higher-level and encompassing. They contain multiple asset twins to study and represent how those assets work together to form a system. Using the car example, a system or unit twin would be the entire chassis of the car; all the mechanical assets combined like the engine, drive train, suspension, etc.

In our process example, a system twin would detail the process of accessing and extracting data from an invoice and inputting that information into a system of record like an ERP (enterprise resource planner) such as Microsoft Dynamics. - Process Twin – A process twin is the highest level of digital representation. It reflects how multiple systems work together to form an entire entity. Using the car example, it would be the whole car itself, but perhaps a better example is a digital representation of how a complete vehicle is manufactured within the factory.

Using our process example, a twin at this highest level would be the over-arching processing of an invoice which includes how data is extracted, inputted, approved, and how the invoice is finally paid and fully processed.

The Benefits of Using Digital Twins

The advantages of using digital twins vary depending on the use case, but from a high level, there are numerous benefits. Primarily, they enable organizations to be more efficient and increase returns. A digital twin provides a tangible source to determine what’s delivering value and what isn’t.

Part of increasing returns off the back of using a digital twin is the cost reduction it enables. Where processes, services, or physical objects aren’t delivering the business value or performing as expected, a digital twin in a virtual environment provides a canvas where improvements can be made to increase that value or performance. This is specifically a result of having real-time data at your fingertips that enables granular monitoring and understanding of performance.

Digital twins also aid change management, helping reduce outages and errors. All processes, services, and systems have dependencies. Digital twins enable you to predict the impact of change and correct it before errors are thrown. Maintenance burdens are radically reduced because maintenance becomes proactive instead of reactive—a feat that has the potential to save companies millions of dollars.

A Digital Twin in Automation

A digital twin in automation is a digital representation of an automated process in one system of record, external to the RPA platform where the automation was deployed and is orchestrated.

In the next article of this series, we dig deeper into the specifics of digital twins in automation including the challenges they solve, the benefits they deliver, and how you can implement digital twins for all of your automated processes.

Share this

Recent Stories

The Benefits of Using a Digital Twin in Automation

3 Common Mistakes to Avoid on your Path to Digital Process Automation